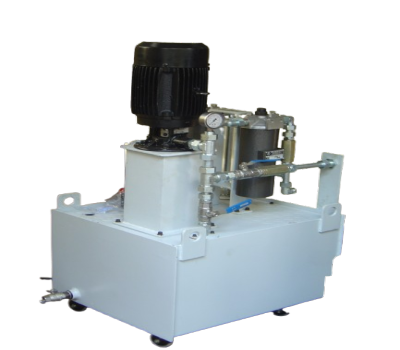

High Pressure Through Coolant System for Precision Machining

Through Coolant Filtration Systems

A Through Coolant Filtration System filters coolant to 10 microns or finer, ensuring clean coolant delivery for high-precision machining. These systems include options like cartridge filters, bag filters and compact band filters, which are selected based on chip volume and filtration needs. Integrated with a high-pressure pump, the system ensures the desired coolant flow and pressure for optimized performance. The high pressure pump in CTS supplies clean coolant through the spindle with the desired flow and pressure

Advantages of Through Coolant Filtration Systems

- Enhanced Rotary Joint Life: Prolongs the lifespan of coolant rotary joints on spindles.

- Optimized Coolant Delivery: Provides precise flow and pressure for efficient operation.

- Finer Filtration Capability: Supports tools with smaller coolant holes for improved performance.

- Seamless Integration: Easily integrates with existing coolant systems.

- VFD Compatibility: Enables adjustable flow and pressure settings for greater flexibility.

key Product

CTS with Cartridge Filters

Key Features

- First Filter: 100 to 200 microns with reusable filter element

- Second Filter: 20 microns with throw-away type filter element

- Coolant Flow: 20 to 30 lpm

- Pressure: 15 to 25 bar

CTS with Compact Band Filter

Key Features

- Coolant Flow: 20 to 40 lpm

- Pressure: 20 to 40 bar

- Filtration Level: Up to 20 microns, with an option for a 10-micron filter

- Minimal Manual Intervention: Designed for ease of use

CTS with Two-Stage Filtration

Key Features

- Coolant Flow: 20 to 40 lpm

- Pressure: 20 to 40 bar

- Filtration Level: Up to 5 microns, optional 10 micron filter

- Minimal Manual Intervention: Requires less operator involvement

Why Choose a Through Coolant Filtration System?

- Versatile Flow Range: Handles flow rates from 20-30 LPM, ensuring compatibility with low-to-medium coolant demands.

- Dual Filtration: Reusable 200-micron filter and disposable 20-micron filter for extended utility.

- Compact Design: Space-efficient system ideal for CNC setups.

- Pressure Range: Supports pressures from 15-25 bar for consistent coolant delivery.

Technical Specifications

Variant | Flow Rate | Pressure Range | Filtration Level | Filter Type |

CTS with Cartridge Filters | 20-30 lpm | 15-25 bar | 20 Microns | Cartridge Filters |

CTS with Compact Band Filter | 20-40 lpm | 15-25 bar | 20 Microns | Compact Band Filter |

CTS with Two-Stage Filtration | Up to 200 lpm | Up to 200 bar | 5 Microns | Duplex Bag Filters |

Explore Our Through Coolant Filtration

END USERS

LEX Through Coolant Filtration Systems can be retrofitted with machines like

![csm_GROB_46c68eea7f[1]](https://lextechnoaid.com/wp-content/uploads/2025/01/csm_GROB_46c68eea7f1.png)

FAQs

It’s a system designed to filter coolant, ensuring clean coolant delivery for high-precision machining.

It maintains coolant purity, improving tool life and machining precision.

Yes, these filtration systems are suitable for precision machining in industries like automotive, aerospace, and medical devices.

Yes, they can be tailored to meet specific flow, pressure, and filtration requirements.