Magnetic Filtration Systems with Precision Drum Separators and Candle Filters

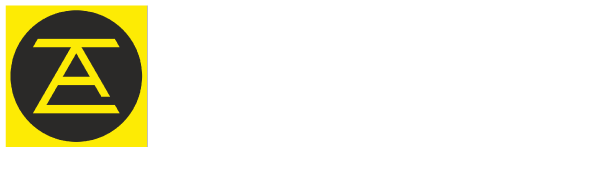

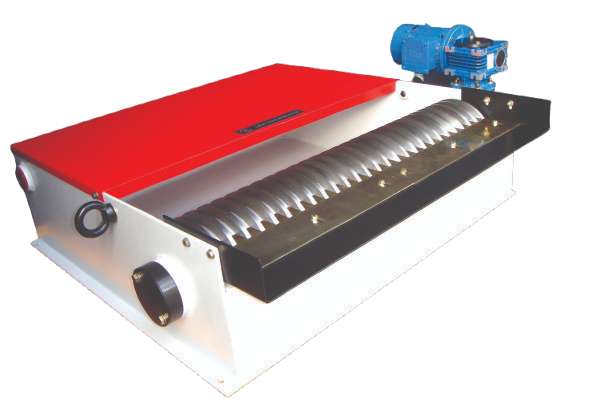

Magnetic Drum Separator

High-Performance Magnetic Drum Separators Manufacturer in India for Effective Filtration

LEX Magnetic Drum Separators are designed to efficiently separate ferrous particles from coolants and any cutting fluids. Magnetic drum separators are available in two variants-Rare-Earth and Ferrite type. Rare Earth Magnetic Drum separators are more powerful & best suitable for grinding and honing operations (powdery chips). Ferrite Magnetic Drum Separators are suitable to handle Sharp as well as Powdery chips.

Benefits :

- Virtually Maintenance-Free Operation

- Reduces Filter Media Consumption of subsequent systems.

- Available in both Grooved and Plain Magnetic Drum types.

- Easy to Install on existing tanks.

- Customizable lengths to suit various coolant flows.

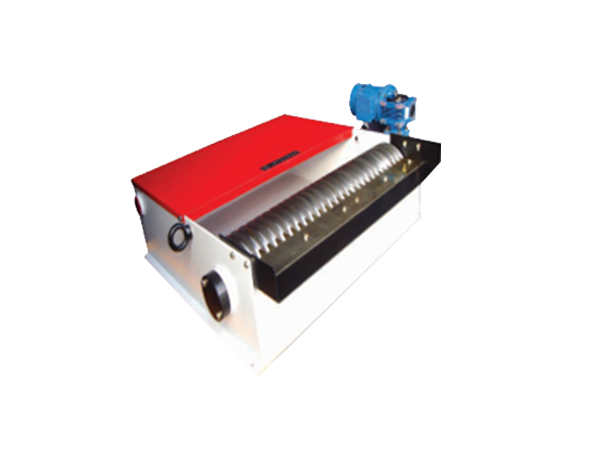

Magnetic Candle

Compact Magnetic Candles for Precise Particle Removal

LEX Magnetic Candles efficiently attract and remove ferrous particles from coolants. The magnetic candle is directly dipped and left into the coolant tank from the top cover plate through a cutout. The magnetic candle absorbs the magnetic particle chips in the coolant. The chips are removed by removing the candle from the coolant tank and wiping the chips off. They are available in Rare Earth and Ferrite Magnet types, ensuring flexible solutions for shop floors and industrial settings

Benefits :

- Easy to Use and maintain.

- Cost-Effective Solution with minimal maintenance needs.

- Loose candles can be carried to multiple coolant tanks for particle removal.

- Available in Ferrous and Rare Earth Types.

- Customizable lengths for specific coolant systems.

Rare Earth Magnetic Drum Separators

High-Performance Magnetic Drum Separators Manufacturer in India for Effective Filtration

Rare Earth Magnetic Drum Separator is highly powerful & best

suitable for grinding and honing operations (powdery chips).

Benefits :

- No Consumables.

- Complete SS Construction & Aluminum Housings.

- Highly Powerful Magnetic Drum with Special Profile-magnets which Can attract very fine chips.

- Negligible Coolant Loss.

Ferrite earth Separator

Compact Magnetic Candles for Precise Particle Removal

Magnetic Drum Separators are used as primary filters to separate ferrous particles from any cutting fluid. Ferrite Magnetic Drum Separators are suitable to handle Sharp as well as Powdery chips.

Benefits :

- Give virtually Maintenance free operation

- Reduce the consumption of Filter Media of the subsequent filtration system

- Available in both Grooved type and Plain Magnetic Drum type

- Easy to install on any existing tank.

- Can be manufactured for different lengths to suit various coolant flows

Applications of Magnetic Filtration Systems

- Grinding Machine

- Honing Machine

- Induction Machine

- Through Coolant System

- Lapping Machine

- Drilling Machine

Technical Specifications

Product | Filtration Type | Key Features | Applications |

Magnetic Drum Separator | Rare Earth / Ferrite | Maintenance-free, Grooved or Plain | Grinding, Honing, Heavy Chip Separation |

Magnetic Candle | Rare Earth / Standard | Portable, Low-cost, Easy to Maintain | Coolant Tanks, Ferrous Particle Removal |

Explore Our Magnetic drum separator and candles

FAQs for Magnetic Drum Separator and Magnetic Candle

Magnetic Drum Separators are typically used as primary filters to separate ferrous particles from any cutting fluid. Magnetic drum separators are available in two variants -Rare-Earth and Ferrite type.

Magnetic Candles can deliver up to 10000 Gauss for efficient filtration.

It efficiently separates ferrous contaminants from dry and wet materials like sand, grains, or powders.

It can handle up to 50 tons per hour, depending on the drum size and application.