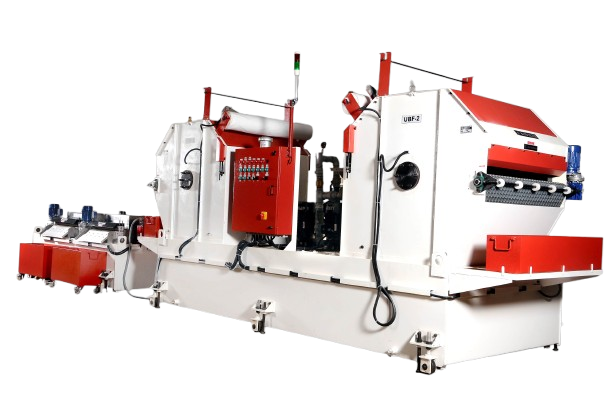

Centralized Coolant Filtration System: Efficient, Reliable and Sustainable Solutions

Transform Your Machining Processes with Centralized Filtration Systems Designed to Deliver Optimal Coolant Quality, Flow and Pressure

Centralized Coolant Filtration System

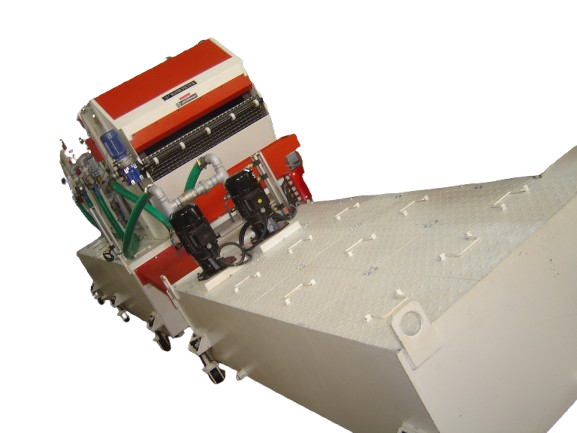

A Centralized Coolant Filtration System is a single system that caters to multiple or all machines in the production shop. LEX Centralized Filtration Systems are designed to supply coolant at the optimum pressure, flow rate, temperature and clarity to multiple machines. This design ensures efficiency and saves significant floor space (often more than 50%) compared to stand-alone coolant filtration systems placed adjacent to each machine. With over 30 years of experience, LEX Technoaid has earned its place as one of the most trusted centralized filtration system manufacturers in India, providing reliable and innovative solutions for coolant management.

Features of Centralized Coolant Filtration Systems

- Low Operation Costs: Running multiple pumps in stand-alone systems will consume much higher cumulative power as compared to running few pumps in a centralized system. Further, these pumps can be connected through VFD to further optimize power consumption. Centralized systems can be programmed to run at lower capacity when not all machines are running in the shop.

- Low Maintenance Costs: These systems require minimal maintenance effort and fewer personnel to manage them. They also require a reduced number and variety of spare parts, which means less storage space is needed for spare components.

- Increased Productivity: To reduce machine downtime, these systems can be provided with stand-by pumps. Productivity is increased as less time is taken to change spares & consumables.

- LEX centralized chiller can be added to supply connected machines with coolant at optimum temperature.

Technical Specifications

Feature | Specification |

Filtration Level | 5–50 microns |

Flow Rate | 20–200 liters per minute |

Pressure Range | 10–200 bars |

Applications | Grinding, Milling, CNC |

Explore Our Centralized coolant Filtration System

FAQs - CENTRALIZED COOLANT FILTRATION SYSTEMS

1. What is a Centralized Coolant Filtration System?

A Centralized Coolant Filtration System is a single system that provides clean coolant to multiple machines in a workshop. It ensures proper flow, pressure, and temperature, making it ideal for operations like grinding, milling, and CNC machining.

2. What industries benefit from these systems?

Industries like automotive, aerospace, and machining shops benefit from centralized filtration systems.

3. How does it improve productivity?

Integrated stand-by pumps and efficient coolant purification systems ensure minimal downtime.

4. Can it handle CNC operations?

Yes, our cnc coolant filtration systems are ideal for precision machining centers.