June 12, 2025 |

Advanced Chip Conveyor Systems Boost Efficiency in Chain Link Manufacturing

Client Overview

A major Automotive manufacturer specializing in automotive chain link components sought to streamline operations in their high-output production facility. Their setup included multiple presses, each producing small-sized chain links along with equally fine swarf, demanding precise and efficient material separation and disposal.

Challenges Faced

The client’s large-scale production setup encountered multiple operational challenges:

- Handling small chain links and fine swarf simultaneously across several machines.

- Inefficient manual transportation of parts and chips to centralized locations.

- Occasional mixing of swarf and job materials, complicating quality control.

- Coolant spills and excess cleaning time caused unnecessary downtime.

- Lack of a system to segregate, collect and transport both components and chips with minimal human intervention.

Solution by Lex Technoaid

Lex Technoaid deployed a complete suite of Advanced Chip Conveyors designed to the client’s operational requirements:

- Each press was equipped with two conveyors—one for chain links, another for swarf.

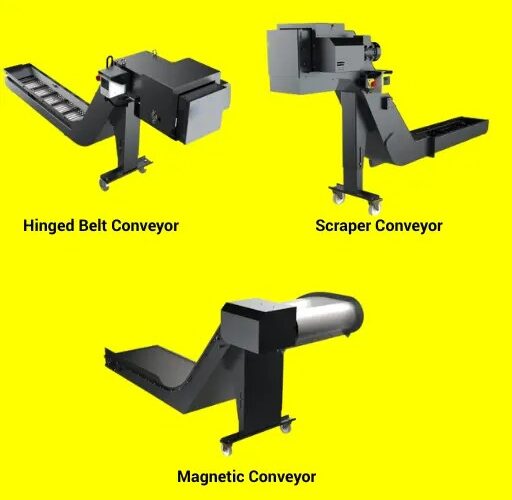

- Based on the nature of the swarf, Scraper Type Chip Conveyors, Magnetic Chip Conveyors and Hinged Belt Conveyors were integrated.

- For presses producing ferrous swarf, Magnetic Conveyors ensured seamless collection and transport.

- All feeder conveyors were connected to a 70-ft-long Centralized Chip Conveyor, designed as a reliable Chip Conveyor line to dispose of scrap directly into collection vehicles and completely bypass manual handling.

- Jobs were transported separately using a dedicated Conveyor with a Self-Cleaning Filter Drum, maintaining material integrity throughout.

- A Centralized Coolant Filtration and chilling system was also provided as part of a unified automation package.

Outcome for the Client

- Shop floor cleanliness improved, reducing coolant spills and swarf buildup.

- By using Chip Conveyors, the part generation rate has been increased to 650 kg/Hr.

- The production capacity has been ramped up by 3 times.

- Cooling efficiency increased with the centralized system, minimizing coolant wastage.

- Achieved a reduction in labour for component unloading and clearing of swarf by 70%.