Customized Filtration Systems for Precision Industrial Applications

Customized Filtration Systems

At LEX, we build filtration systems for several applications like :

- Turning

- Machining

- Grinding

- Honing & Lapping

- Gun Drilling

- Hydraulic oil filtration system

- Component washing and ECM

- And others

Applications of Individual Filtration Systems

Individual systems are perfect for:

- Precision machining in medical devices and electronics industries.

- Small-scale manufacturing and custom tool-making operations.

- Grinding and honing machines in automotive workshops.

- CNC machines need a fine chip and particle filtration.

- Metalworking processes such as milling, lathing, and cutting.

Features of Individual Filtration Systems

- Customization: Tailored to meet specific equipment needs for maximum efficiency.

- Flexibility: Suitable for facilities with diverse machining processes.

- Scalability: Easily expandable to adapt to changing production demands.

Turning machine filtration systems

LEX Turning machine filtration systems offer the following salient features:

- Simple and easy to integrate with CNC machine

- Robust construction, minimal maintenance

- Extended machine life due to consistent filtration of coolant

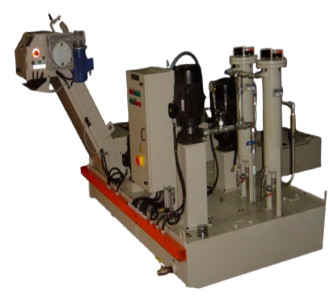

Coolant filtration system for Machining centres

LEX Machining centre filtration systems offer the following salient features:

- Chip conveyor, filtration, through coolant setup built in a single package

- Plug and play integration with CNC machine

- Integrated with LEX chiller to maintain optimum coolant temperature

- Improved component accuracy and extended machine life owing to consistent filtration of coolant

Grinding machine filtration systems

LEX Grinding machine filtration systems offer the following salient features:

- Highly powerful Rare Earth Magnetic Drum Separators reduce consumable cost

- Integrated with LEX chiller to maintain optimum coolant temperature

- Improved component accuracy and extended machine life owing to consistent filtration of coolant

- Compact U Band Filters and Cartridge/Bag filters designed to provide filtration up to 5 Microns

Coolant filtration system for Honing and Lapping machines

LEX Honing and Lapping machine filtration systems offer the following salient features:

- Highly powerful Rare Earth Magnetic Drum Separators reduce consumable cost

- Integrated with LEX chiller to maintain optimum coolant temperature

- Improved component accuracy and extended machine life owing to consistent filtration of coolant

- Systems are designed to ensure minimal oil wastage

Gun Drilling filtration systems

LEX Gun Drilling filtration systems offer the following salient features:

- Filtration level up to 5 microns can be provided

- Chiller removes the heat from coolant due to friction and cutting

- Programmable flow and pressure control eliminates manual intervention

- Suitable for single and multi-spindle applications

- Reduction in wear of gun-drills and guide bushes

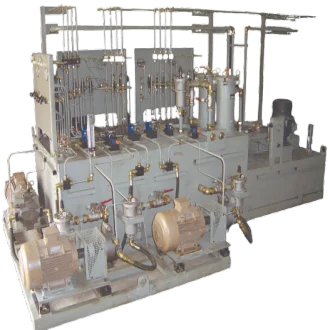

HYDRAULIC OIL FILTRATION SYSTEM

LEX Hydraulic Oil Filtration Systems have the following benefits:

- No downtime as oil is cleaned continuously when machine is in operation.

- Less component wear, achieves extended life of hydraulic components.

- Avoids frequent breakdowns.

- Helps to retain original oil properties for a longer time.

- Improves efficiency and overall system performance.

FILTRATION SYSTEM FOR COMPONENT WASHING MACHINES

FLUID FILTRATION SYSTEMS

LEX Washing Machine Filtration Systems have the following benefits:

- Achieves effective cleaning of the component with clean fluid

- Helps prevent the accumulation of contamination within the tank.

- Achieves Filtration level up to 5 microns

- Integrated with heater to maintain the right temperature of the cleaning fluid

- Provided with easily replaceable filter media.

FILTRATION SYSTEM FOR ELECTROCHEMICAL MACHINING

Electro Chemical Machining uses electrolyte for material removal process. Designed for the filtration of liquids used in ECM process, these filtration systems are manufactured using different grades of Stainless Steel to withstand corrosive liquids.

LEX ECM Filtration Systems have the following benefits:

- Enhances life of electrolytes

- Helps to prevent the accumulation of contamination within the tank.

- Achieves Filtration level upto 5 microns

- All system components are suitable to handle corrosive liquids

- Provided with easily replaceable filter media.

Explore Our Customized Filtration System

FAQs

Industries such as automotive, medical devices, aerospace, and metalworking benefit greatly from customized filtration solutions.

The maintenance schedule depends on the type of filter and the nature of your operations. We provide guidelines and support for filter maintenance.

Yes, our systems are designed with energy efficiency in mind, helping you reduce operating costs without compromising performance.

Absolutely! Our filtration systems are designed for seamless integration with your current machinery setup.