In modern manufacturing, even microscopic contaminants in cutting fluids can cause significant damage to tools. These issues impact surface quality and result in increased machine downtime. As industries adopt high-speed and high-tolerance machining processes, the need for reliable magnetic filtration becomes essential.

The Challenge of Ferrous Contaminants in Coolants

Grinding and Drilling machines continuously generate ferrous particles from workpieces and tools. These fine metal chips mix with coolants and recirculate through the system. Over time, they cause problems including

- Excessive wear on grinding wheels.

- Poor surface finish.

- Higher maintenance frequency.

- Damage to pumps and internal components.

This challenge is critical in Grinding and Honing operations where clean coolant flow is a key requirement. Traditional filtration systems like bag filters or gravity-based units often fail to capture particles below 10 microns.

Magnetic Filtration as a Reliable Solution

Magnetic Filtration Systems remove ferrous particles using strong magnetic fields. A Magnetic Separator can be installed at the primary stage to remove fine chips before they reach secondary systems or critical components. This protects machines from internal wear and ensures cleaner operations.

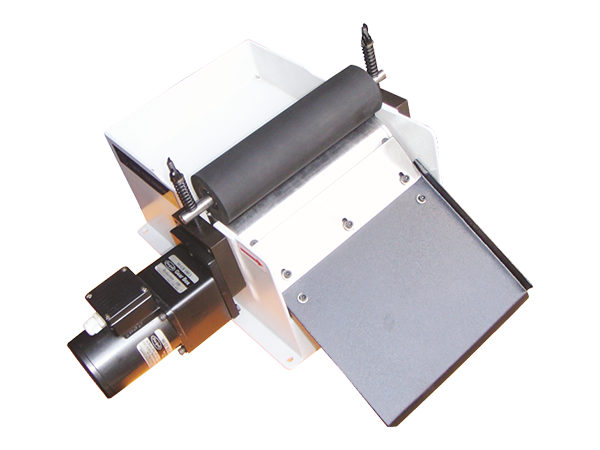

A Drum-Type Magnetic Separator provides continuous separation without stopping the coolant flow. These systems do not require consumables and deliver uninterrupted filtration.

Key Advantages of Drum-Type Magnetic Separators

Magnetic Drum Separator offers multiple benefits in coolant management. These include

- Maintenance-free operation.

- Reduction in filter media usage.

- Improved coolant life and tool performance.

- Enhanced surface finish on components.

- Lower machine wear and reduced repair needs.

They improve process stability while decreasing operational costs across machine shops and production lines.

Reduced Downtime Through Efficient Filtration

With clean coolant, shops experience fewer clogs and longer intervals between maintenance. Tool wear slows down and machine uptime improves.

This contributes to:

- Fewer production halts.

- Lower tool replacement expenses.

- Better coolant system efficiency.

- Reduced sludge formation.

Filtering ferrous particles early prevents buildup in lines and keeps machines operating at peak levels.

Application Areas of Magnetic Filtration Systems

Magnetic Separators are widely used in,

- Grinding machines

- Honing machines

- Lapping machines

- Drilling machines

- Through coolant systems

- Induction hardening machines

- Component washing machines

These machines require consistent coolant quality to maintain tight tolerances and minimize rework.

Final Word

Shops aiming to reduce tool wear and prevent unexpected maintenance stoppages can rely on Magnetic Filtration as a dependable solution. Drum-Type Magnetic Separators and Magnetic Candle units help eliminate fine ferrous particles from the source. These systems protect equipment and extend tooling life without recurring media costs. To meet these exact needs, Lex Technoaid offers advanced magnetic separator solutions built for high-performance machining environments.

Ready to upgrade your coolant management and boost productivity? Visit us at www.lextechnoaid.com or call us on +91 99166 98105